The organization can track where items are

in-process at any time. So, if something hinders the progress, the alerts and

notifications automatically get delivered to the authorized officials, so that the

appropriate action could be taken immediately without any further delay.

Moreover, for employees, it’s very convenient since they don’t need to remember

all the rules that apply to a particular process; the system takes care of all.

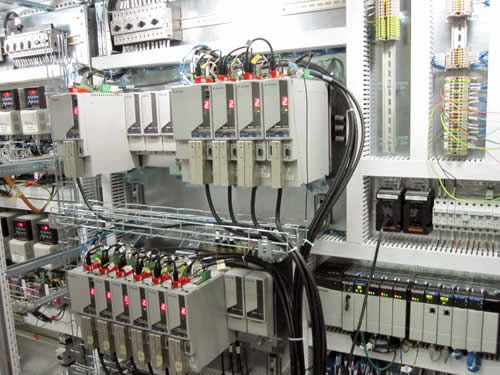

This is when Automation Services test equipments come into limelight that

not only saves on time but are more efficient than humans when it comes to

preciseness. Such equipments help to maintain the compliance and standards that

are critical to the production of next batch of products and delivering them

into the market. As compared to mechanization that requires human involvement

for its operation, the fully automated test equipments require least or no

human intervention for carrying out the testing process. The equipment itself

diagnoses the issues, analyze them and then represent it in human readable form

and all this is done by the specific software integrated with the appropriate

hardware device. With human intervention, it’s not possible to maintain the

integral aspect of the testing. This increases the chances of releasing

defective products in the market, which can instead cost the companies in many

ways – the major impact is that it can ruin the company’s reputation. As a

result, the customers will opt to go to other big players and your rivals.

AutomationControl Systems

test equipment can also be used for testing RF products. For example, testing

of 100 units of WAN RF Global MODEM for Functional Test which involves full

validation of output power, carrier frequencies, bandwidth, SPUR (Spurious

Response) measurements and SNR (Signal to Noise Ratio) could be a worst

nightmare of Technicians. However, for an ATE, it’s a matter of seconds. Traditionally,

ATEs were best utilized for testing high volume of manufacturing products -

mainly because of the capital expenditure, and development costs involved.

However, with the technological advancements and new devices emerging, this is

no longer the case. Test Equipment Automation takes up the entire

responsibility, be it for small scale industry or large scale industry, to test

and validate the processes, in order to optimize throughput, improve product

quality and increase profitability.

The next advantage is that it saves labor

cost while accelerating task completion. The functionality of the existing

systems can be extended by integrating with other solutions, providing

flexibility to the businesses to enhance business processes accordingly without

much investment on the complete makeover of the tool. Apart from consistency,

it ensures accuracy in every operation, reducing the chances of surplus

resource drain and data discrepancy. With the shortage of skilled IT workers

and strict budgets, there is a lot of need in the current scenario of such a

robust solution that is capable of handling simple to complex tasks on its own.

The inefficiency cannot be accepted and time is crucial at every point.

These situations represent an opportunity for process automation software that

could help crack the complexities involved in the business operations and

deliver agility at every step to bear long-lasting fruitful results.